Our old system in a high-impact area had to be recalibrated every day. After four years of working with JoeScan scanners, now I only check them once a month - and they're just how I set them.

Phil Loder,

Timber Automation & Control

Precision Performance Without the Expensive Upgrade

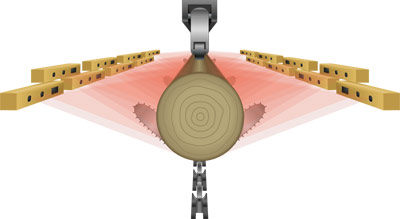

Many mills are finding that a short infeed JS-25 optimized sharp chain offers one of the best values around. You can get full auto-rotation and skew, with the low cost, easy maintenance and reliability of a sharp chain infeed. Previously, these benefits required million-dollar upgrades to huge and complex double-length infeed systems.

Output that Matches Your Optimizer

One of the biggest problems in any optimized system is ensuring the piece doesn't move after it has been scanned. With a well-designed sharp chain infeed, you get a full 3-D scan of the log after it is fully impaled on the sharp chain, leaving minimal opportunity for the log to shift before hitting the saws. Customers with JoeScan scanning systems are continually amazed at how precisely the boards and cants coming out of their sharp chain match what the optimizer was attempting to produce.

Is your scanning system effective?

The key test of any scanning system can be summed up with a single question: Does your actual output consistently match what your optimizer claims? If not, then you have an opportunity to significantly improve recovery with a JoeScan system.

Our recommendation

For sharp-chain scanning applications, we recommend using either the JS-25 SX or the JS-25 X2 or X3 models. The SX is effective in most single-zone applications; the X2 dual-laser model (12” spacing) and the X3 triple-laser model (6” spacing) excel at high-density snapshot and short-infeed scanning.

Product Specs

| Max Resolution: | X2 and X3 – +/- 0.030” |

| Placement Flexibility: | X2 – 2 lasers 12” apart X3 – 3 lasers 6” apart |

| Max Scan Rate: | X2 – 425 profiles/sec. per laser X3 – 283 profiles/sec. per laser |

| Depth of View: | X2 and X3 – 3’ to 8’ |

| Field of View: | X2 and X3 – 48” @ 96” |