A first generation JoeScan returns home in great shape

Repair Shop Stories #689

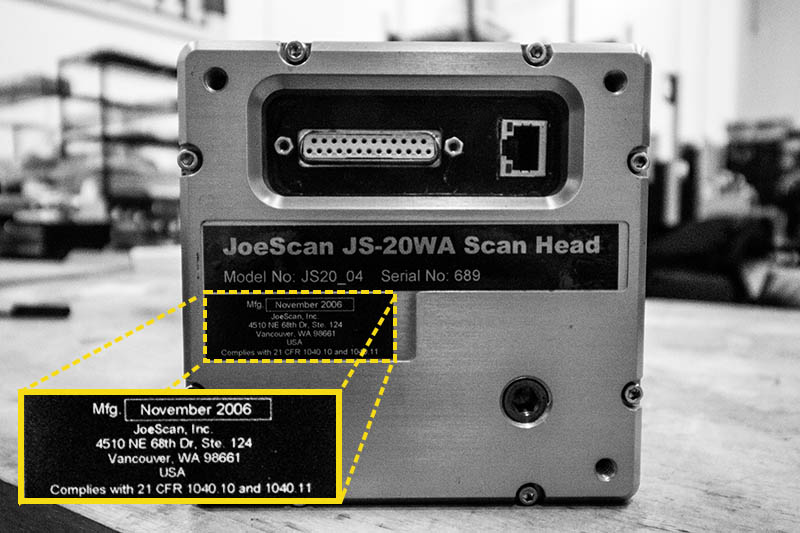

This JS-20WA scan head came in for a quick tune-up after 12 years of hard work.

Serial number #689 made its first appearance in the repair shop last month, and we haven’t seen it in quite some time!

This wide angle 3-D laser scanner is a first generation JoeScan. It was originally shipped out to a sawmill customer way back in November of 2006. Notice that DB25 D-sub connector next to the ethernet port? What a dinosaur!

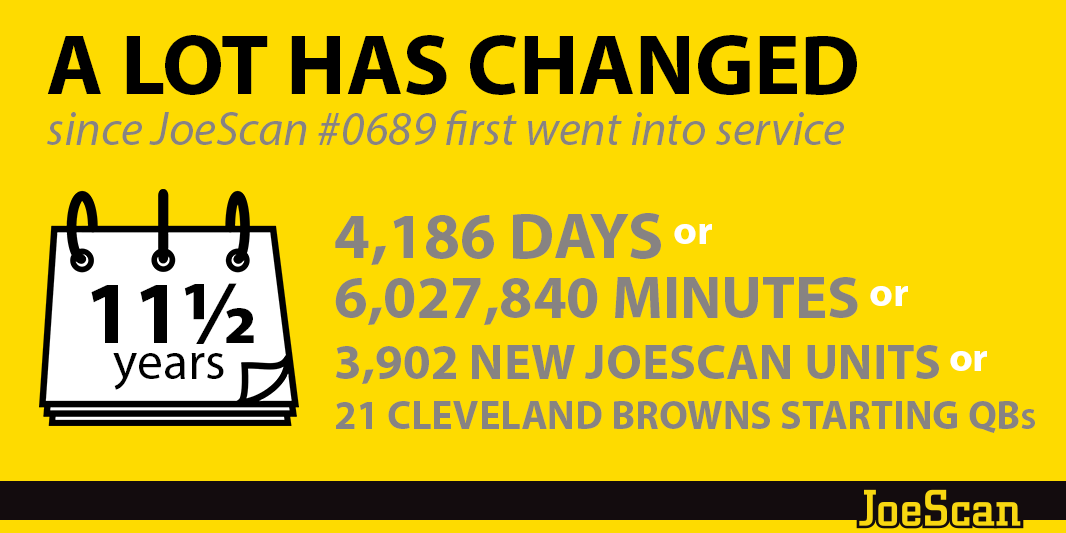

We’ve come a long way in the 11½ years since this unit was a shiny new scanner, but one thing hasn’t changed: JoeScans are still built to last. So what was the reason this unit needed a checkup from our hardware doctors?

The culprit. Room Temperature Vulcanizing adhesive.

After more than a decade of generating precise 3-D scans of boards in a harsh sawmill environment, the RTV adhesive in this unit had begun to decay, creating gaps in the seal of the aluminum housing. These gaps allowed some moisture inside, which fogged up the windows and prevented our lasers and cameras from doing their job.

Just three things to get this old workhorse back to factory fresh condition.

In fact, when we opened #689 up, everything INSIDE was working just fine! We just needed to dry it out, give the windows a quick washdown, and put a new layer of adhesive down. In typical JoeScan fashion, we had the scan head back out to the job site in a flash, so it could get back to doing what it loves best: scanning lumber.

Our latest generation of scanners feature a revamped gasket system to protect even further against moisture issues, and we put each and every unit that leaves our shop through a rigorous vacuum seal and pressure test. This is how the JoeScan team can ensure that our products are the longest lasting, hardest working scanners you can use in your sawmill.

Have questions about warranties, repairs, or extending the life of the scan heads on your line? Let us know by filling out a comment below or contacting us at sales@joescan.com